Microcontroller software example¶

This document describes a stripped-down version of the python code developed for the DTA system, intended to provide a more easy to follow demonstration of the underlying processes going on in the full implementation.

The stripped-down version of the code is (mostly) contained within a single file, main.py, which carries out an approximately equivalent routine to the full microcontroller code, without the use of programming abstractions such as separate classes and modules.

Requirements¶

In order to properly familiarise yourself with the effects of each part of the code you will need the following items:

A Raspberry Pi Pico, with headers attached, running CircuitPython (7.3.3, preferably). Instructions on how to install CircuitPython here.

A Windows or Linux computer, with the Python editor Thonny installed. Also needed is a serial client application. PuTTY, available on both Windows and Linux, is an excellent choice for this and is the client used in this tutorial.

A Micro USB cable to attach the Pico to the computer

At least one Adafruit MAX31865 RTD amplifier breakout board and an accompanying RTD temperature sensor

At least one Adafruit MAX31856 Thermocouple amplifier breakout board and an accompanying thermocouple temperature sensor

For proper demonstration of temperature control, a thermoelectric module (TEM), DC power supply and HAT-MDD10A H-Bridge motor controller are strongly recommended.

It is feasible to substitute the H-Bridge controller with an appropriately spec’d high-side or low-side logic-level MOSFET - such as the FQP30N06L - using the PWM output of the MCU to control the MOSFET’s gate terminal. However, if doing so, you must edit lines 435 and 437, making sure to set the value of both PWM pin’s duty cycle to zero, when

u<0.Wires and preferably a small breadboard to connect everything

Hardware setup¶

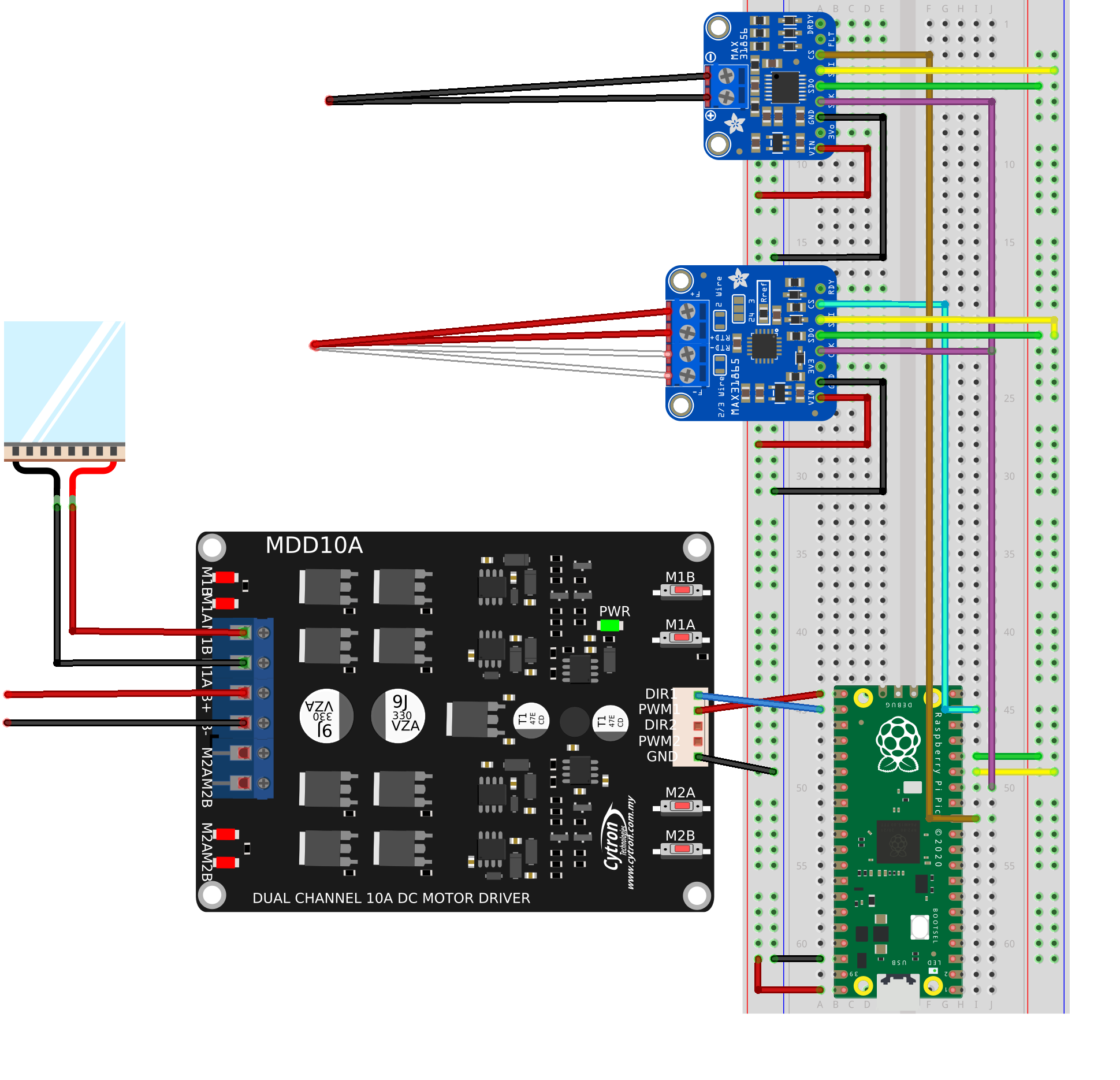

With all of the necessary parts obtained, you will need to connect the electronics according to the following diagram:

The unconnected red and black wires on the left-hand side of the diagram should be connected to the positive and negative connections of the DC power supply, respectively.

For the purposes of demonstrating temperature and heat control, the thermocouple and RTD sensors can simply be attached directly to one of the faces of the thermoelectric module. We will want to attach it to the side that gets hot (the other side will cool down), which depends on the direction of the current that drives it.

You can test this yourself, by using the buttons marked M1B and M1A. These buttons allow the H-Bridge to be manually controlled, with one button providing forward current and the other reverse current.

Pressing down M1A, you should find that one side of the TEM heats up, whilst the other side cools down. With M1B pressed down instead, you should find the sides are now reversed i.e the previously hot side is now cold and the previously cold side now hot etc.

For the MAX31865 amplifier board, you may need to short some of the solder bridges arranged on the board, depending on the number of wires used for your RTD sensor. You can find more information about this in the Adafruit online instructions.

Software setup¶

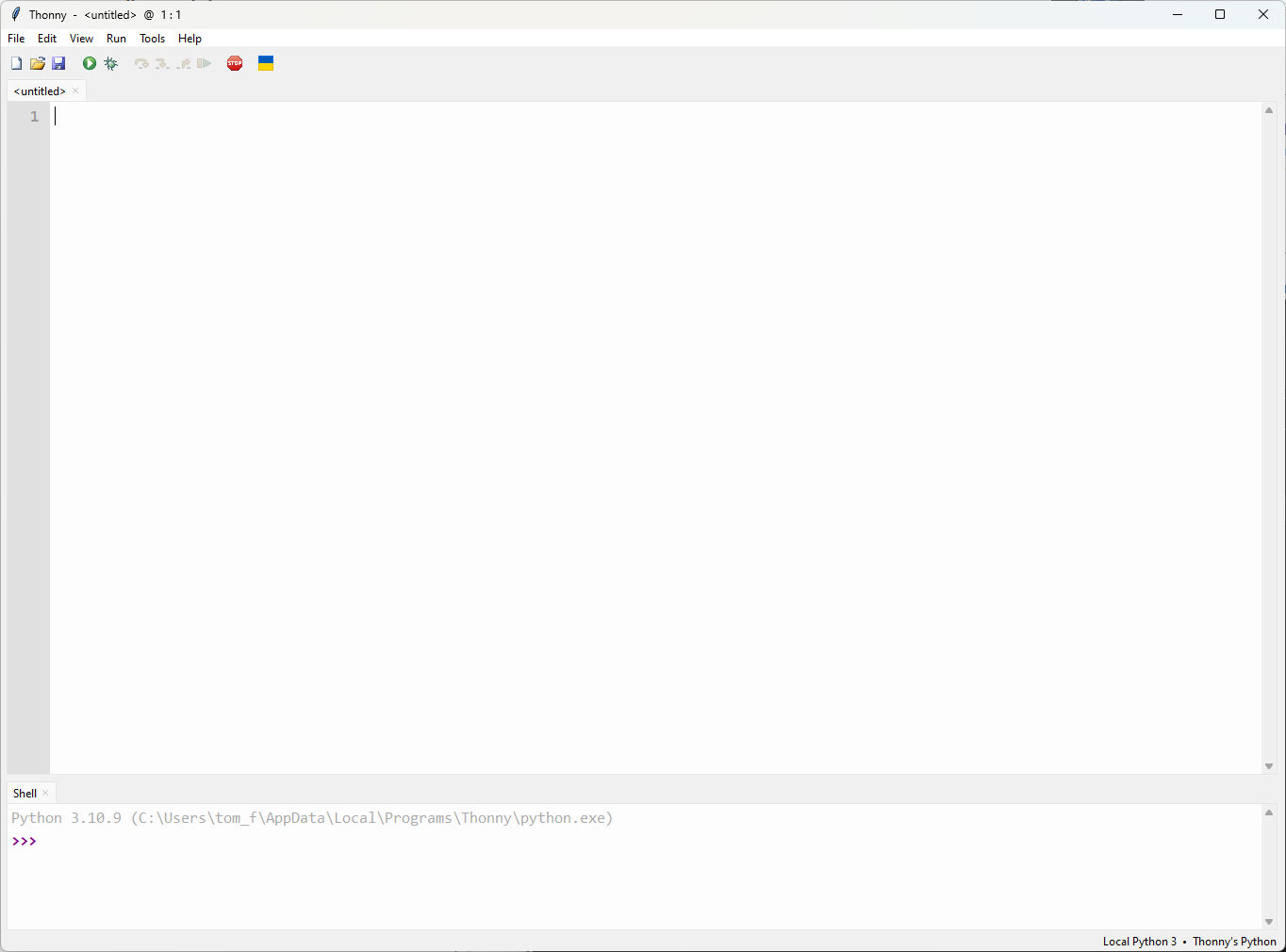

With Thonny and a suitable serial communication application installed, you should open Thonny up, which should look somewhat similar to the picture below:

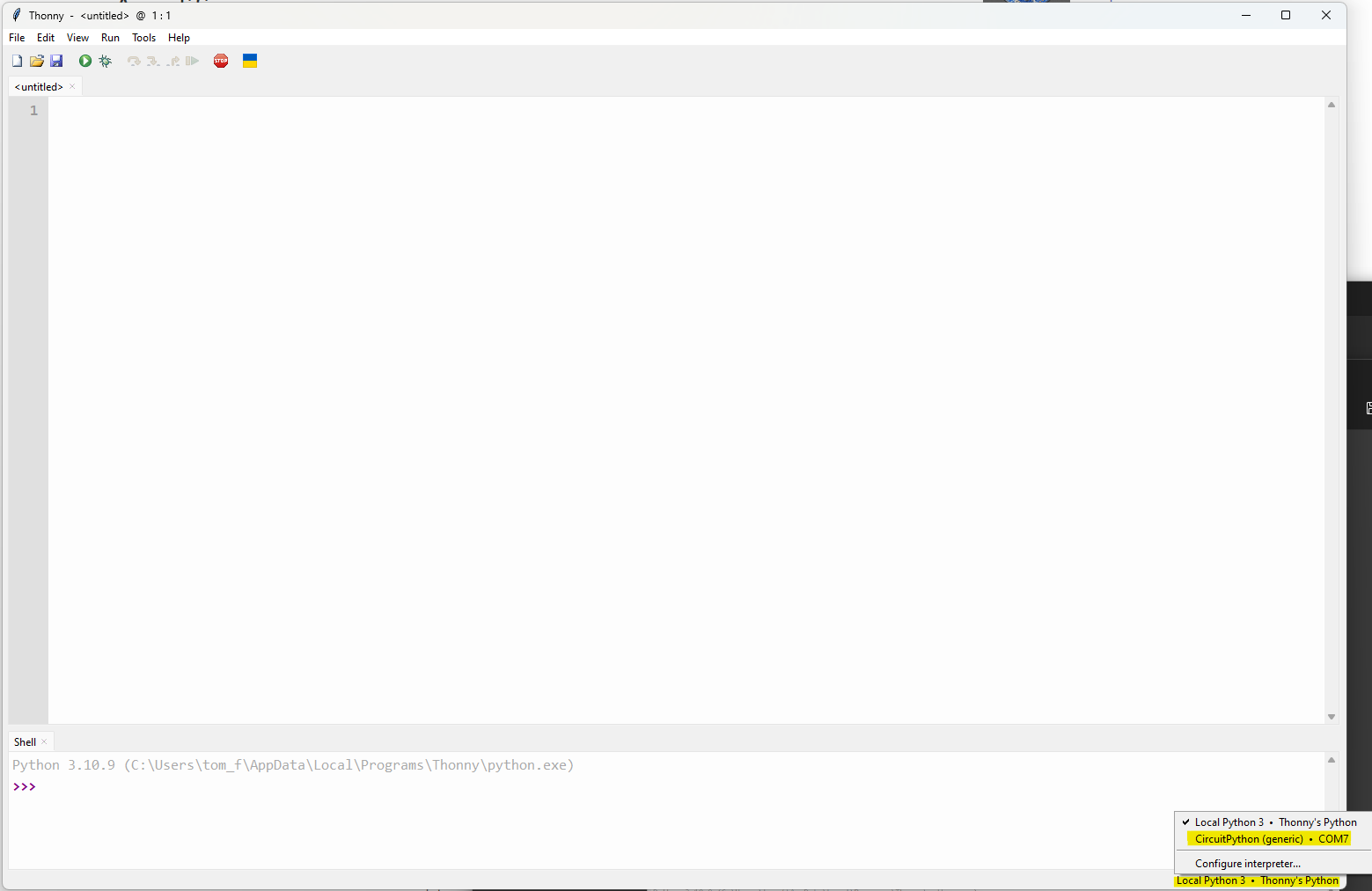

We can see in the bottom right hand corner that the current interpreter is configured to the local Python 3 installation on the computer. We therefore need to change this to the CircuitPython interpreter, that is on the Pico. With the Pico plugged into the computer via the USB connection, left-clicking the interpreter in the bottom right-hand corner should result in the following menu, from which you should select CircuitPython:

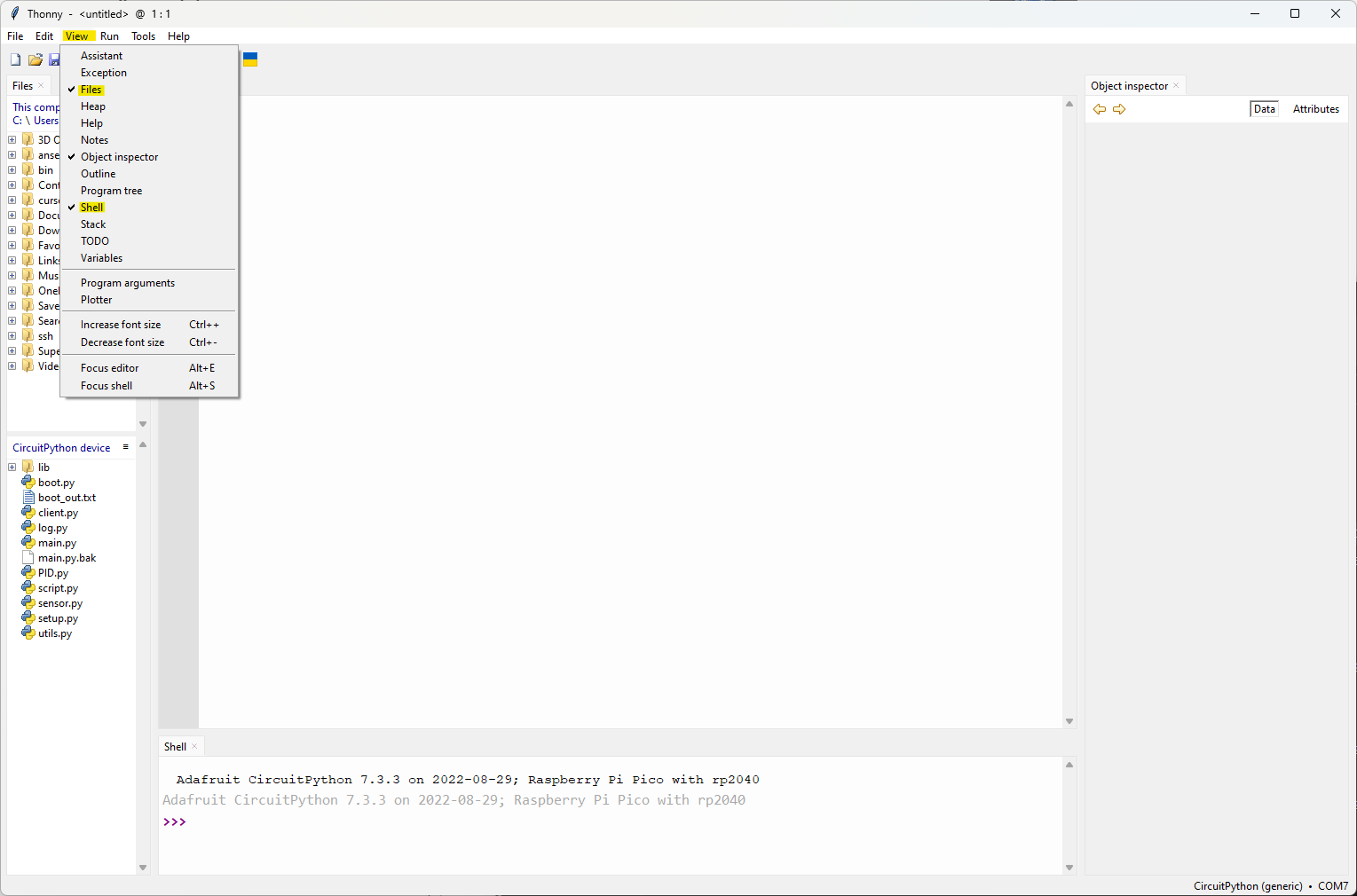

Next, we will want to configure the user interface, to show the necessary elements. You can do this by clicking the “View” menu, making sure that the highlighted options are selected:

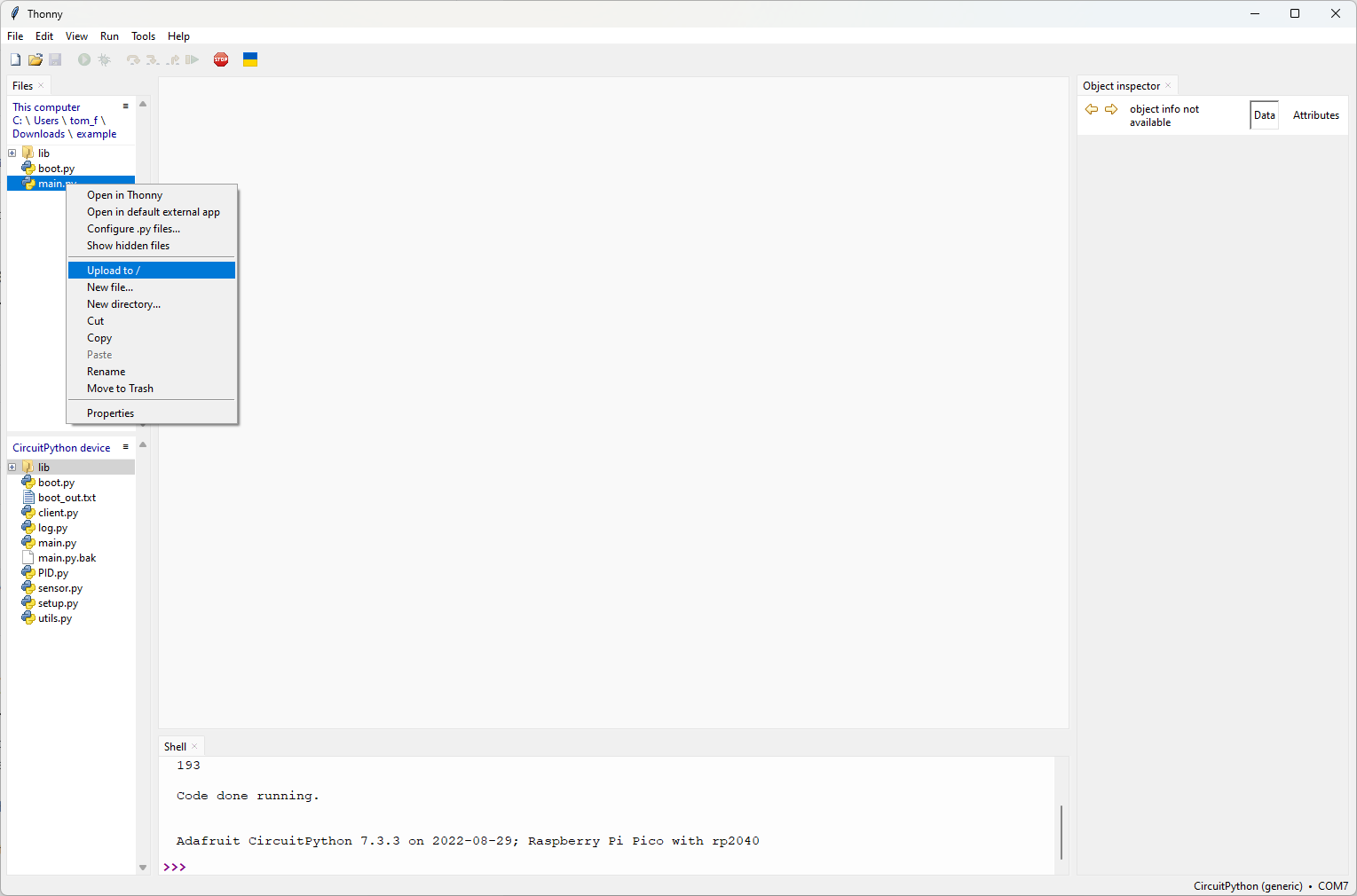

You will probably notice that the Files menu shows two filesystems, namely that of the local computer, as well as that of the microcontroller. In order to install the python code used for this example, you will need to navigate to where the files are stored on your own computer, from which you should be able to copy them to the microcontroller by right-clicking on them as shown below:

With the main.py and boot.py files, as well as the lib directory, copied to the Pico’s filesystem, you can open the version of main.py installed on the Pico by double clicking it.

Inspecting the program¶

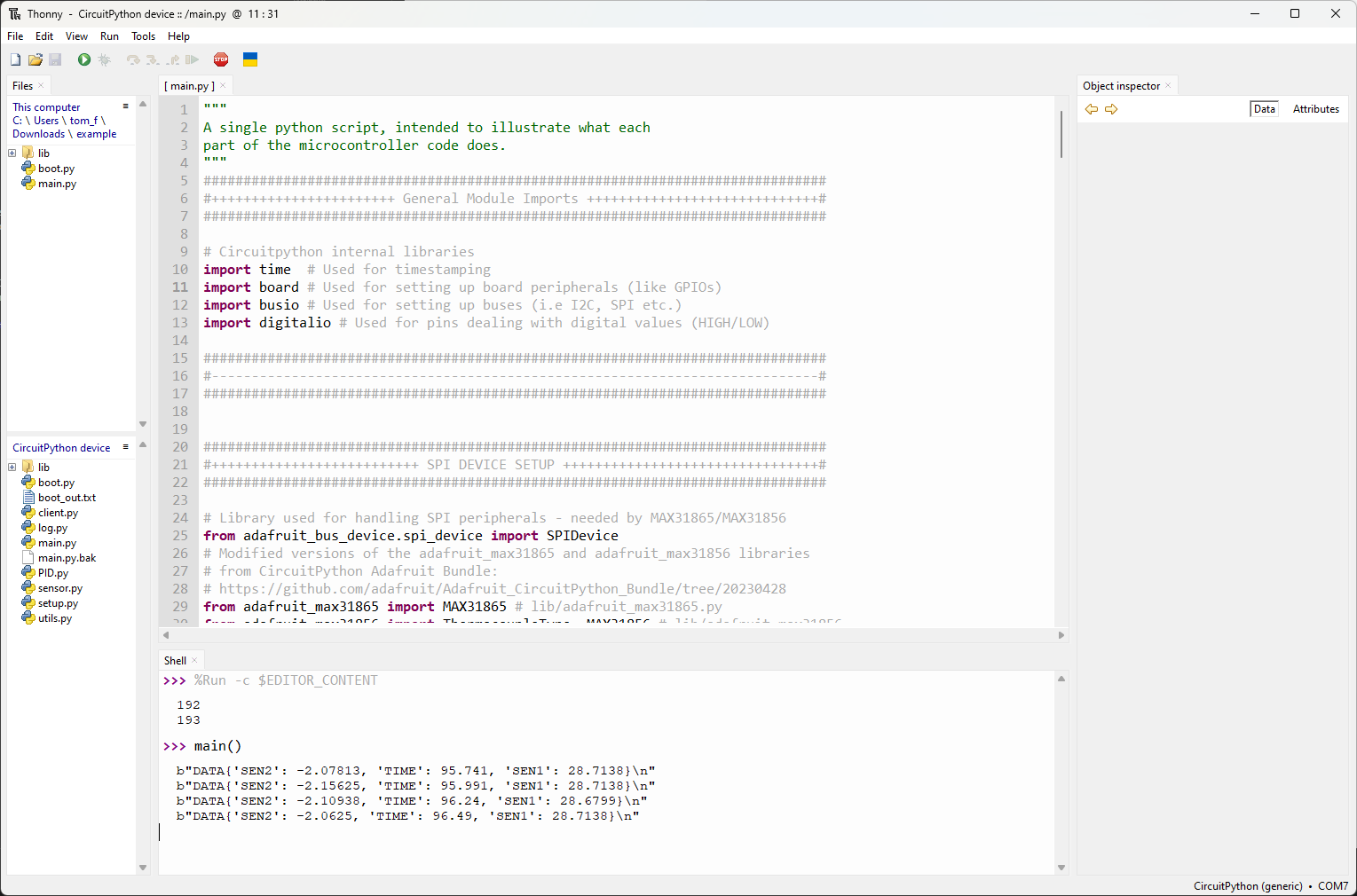

Upon opening main.py, you should see an approximately 450 line python program, which has been divided into headered sections by the inline comments.

The first 140 lines of code largely consist of boiler-plate code, such as pin definitions, module imports and setting up periperhal devices.

Lines 10-13 import the basic interal Circuitpython libraries that are required for measuring time, accessing board peripherals (like GPIO pins) and buses such as the I2C, I2S, SPI, UART buses etc.

Lines 24-100 involve the initialising of the SPI devices, which in this case, are the MAX31865 and ‘56 breakout boards. If you lookup a pinout of the Pico, you will see that the pin definitions specified in lines 33-35 match the pins used in the wiring diagram shown earlier.

Between lines 52 to 100, the python objects used to model the two breakout boards

are initalised, max31865 and max31856.

Temperature sensors¶

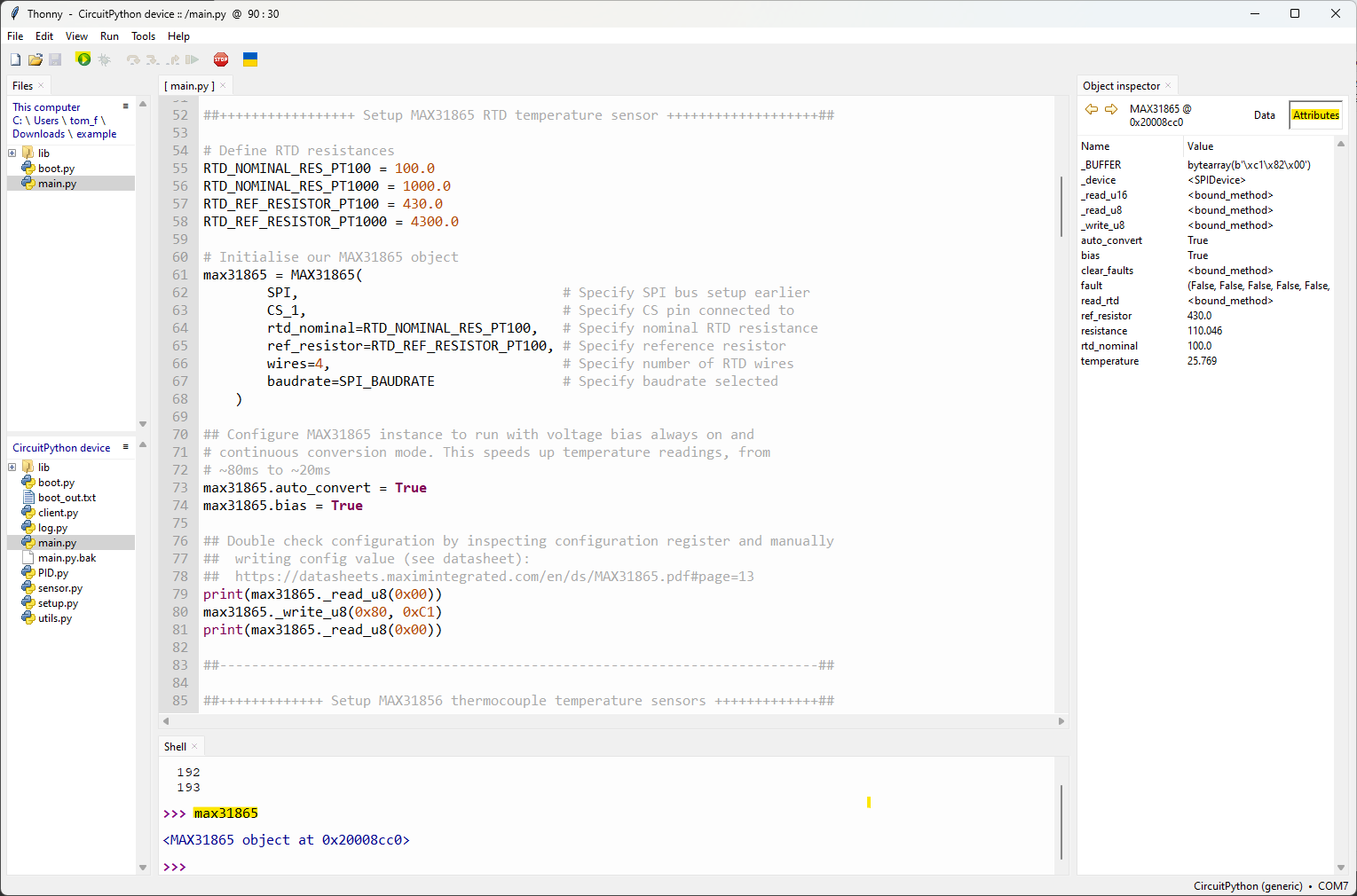

We can get a better understanding of these objects by running the program and

inspecting them in the object inspector. Press the green “Run” button, to

run main.py and then type max31865 in shell prompt, hitting enter.

You should notice a new object appear in the Object inspector view. Clicking

on the Attributes tab will display the class features of the max31865

object, including its attributes and methods. You will probably notice that

the value of some attributes, such as ref_resistor and rtd_nominal

match those specified in the object’s constructor.

Now try entering max31865.temperature in the shell prompt and pressing

enter. This should return the current temperature detected by the board. You

should notice that when touching the RTD sensor, the temperature goes up.

PWM and DIR pins¶

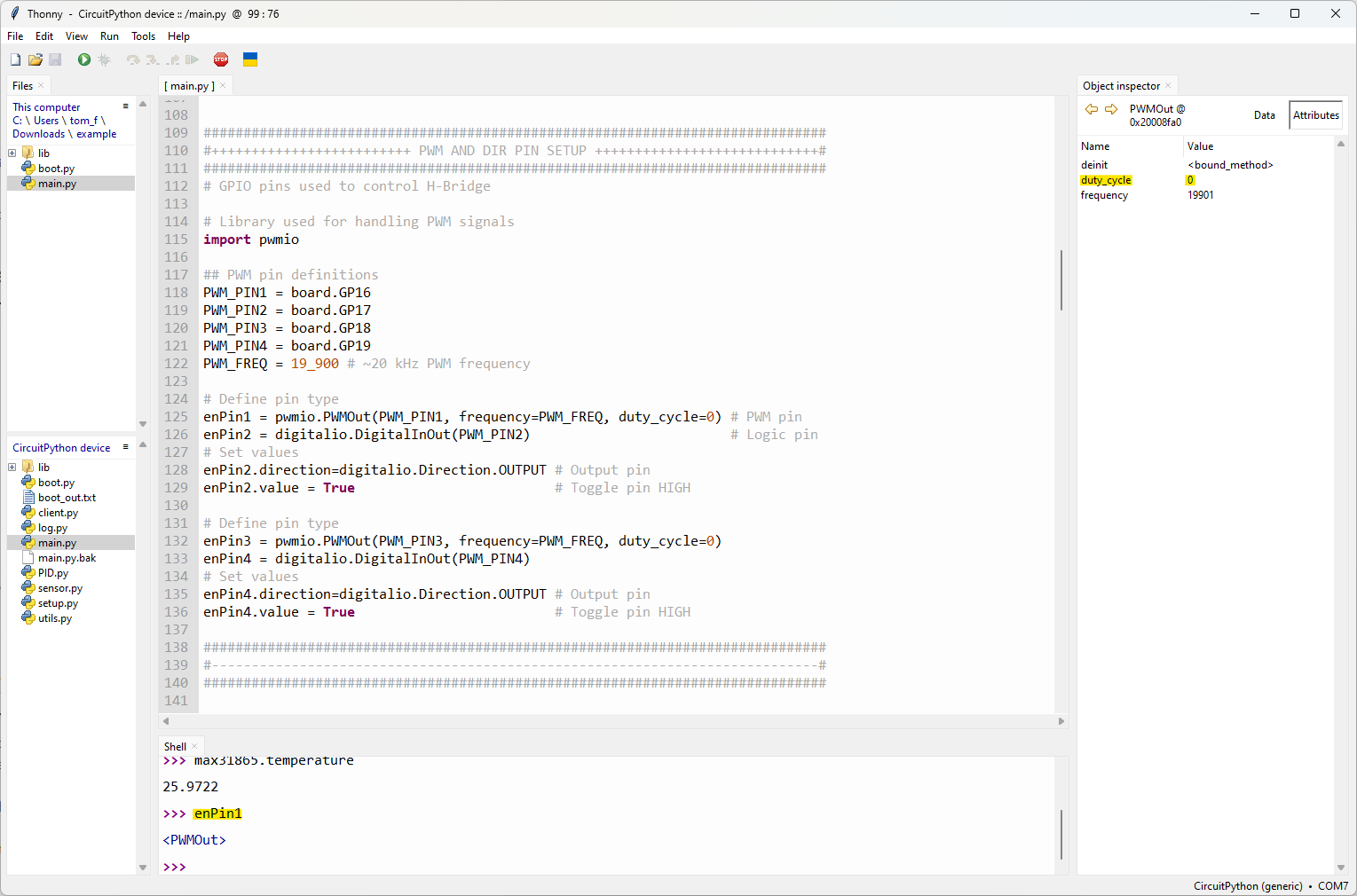

Lines 115-136 involve the setup of the pulse-width modulation and logic output pins, used to control the H-Bridge.

Once again, looking at the pin definitions, you will see that they match that of the wiring schematic shown above.

Two pins are used to control a single thermoelectric module:

The PWM pin controls the amount of current provided by the H-Bridge to the thermoelectric module. It does this by rapidly toggling on and off, at a relatively high frequency. The amount of time that the pin is LOW, relative to the amount of time that it is HIGH, determines the amount of current delivered - a value that is referred to as the duty cycle. For example, if the pin is high 70% of the time and low 30% of the time, it has a duty cycle of 70% and 70% of the maximum current will be provided to the TEM.

The DIR pin controls the direction of the current flow through the TEM. When the DIR pin is HIGH, current will flow one way through the TEM; when it is LOW, the current will flow in the opposite direction.

Once again, you can test these ideas, by typing enPin1 into the

shell prompt. In the object inspector you should see a PWMOut object,

with a duty_cycle attribute.

Try changing this, by entering enPin1.duty_cycle = 16383 in the shell

prompt. Do you notice anything happening with the TEM? Now try modifying the

value of the direction pin, by entering enPin2.value = False. Once again,

you should notice a change in the response of the TEM.

Serial communications¶

The reference documentation for the microcontroller software describes the background behind the communication between the MCU and software running on the Raspberry Pi.

This communication is carried out over a serial connection, which is a basic way for low-power devices to exchange information, typically in the form of byte-encoded strings.

The actual transport medium for the serial communication between the MCU and Raspberry Pi in this case is the USB connection. The Rasperry Pi Pico is capable of using a USB standard called USB-CDC, which allows it to emulate a serial port on the connected computer, appearing as a virtual COM port.

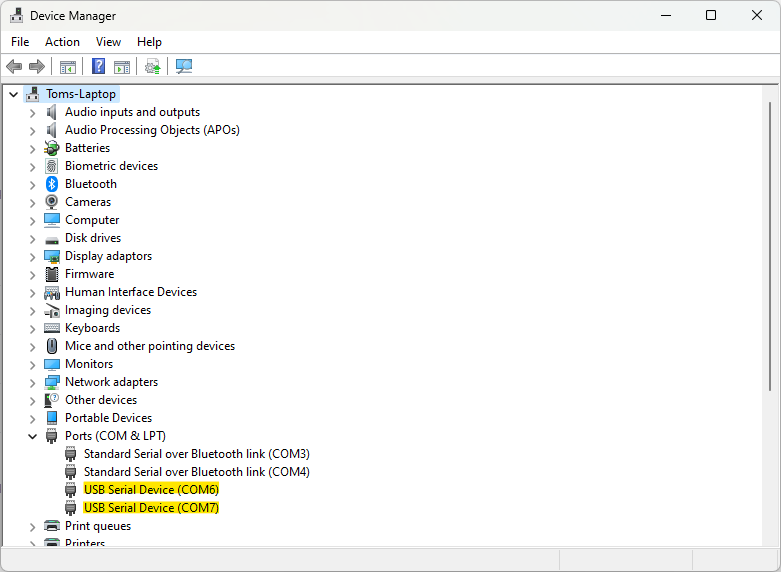

On Windows, this can be seen in the Device Manager, as entries under the Ports (COM & LPT) heading, as in the picture below:

We can see that two serial devices are listed, COM6 and COM7. Looing back at the earlier figure, where we selected the CircuitPython interpreter, you will notice that this was COM7. Indeed, in CircuitPython, normally only one COM port would appear on the computer - the one associated with the REPL shell that we’ve been using in Thonny.

If you open the file boot.py, you will notice that it contains an

import statement for the CircuitPython usb_cdc library, as well as

a function call featuring that library, on line 9. Inside the function

argument, both of the parameters, console and data are set

as True. By default, only the former is normally enabled, providing

the REPL prompt. By enabling data, we get an extra serial channel,

which can be used to pass messages from the computer to the Pico and vice

versa.

Let’s try this this out. If you haven’t already, press the red “STOP”

button in the Thonny interface to restart the Pico. This is necessary

because the boot.py file is a special python file, that is

executed when the Pico initially boots. Therefore, even if you’ve copied

it to the Pico’s filesystem, until the Pico reboots, it won’t have any

effect. Upon rebooting, press the green “Run” button again to execute

main.py

You should now see two USB serial devices listed in Device Manager under different COM ports, where one matches that used by the interpreter in Thonny and the other does not.

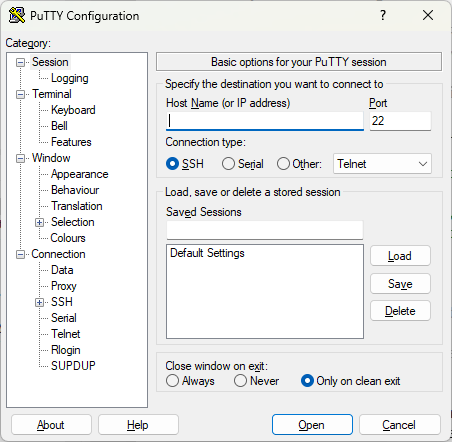

Now open the application PuTTY. You should see something like the following:

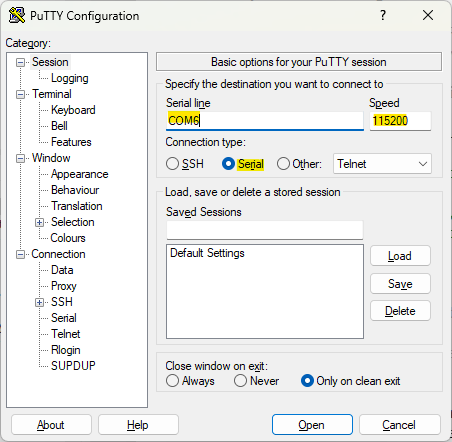

Change the connection type to Serial, entering the COM port that isn’t being used for the REPL interpreter and setting the “Speed” value to 115200:

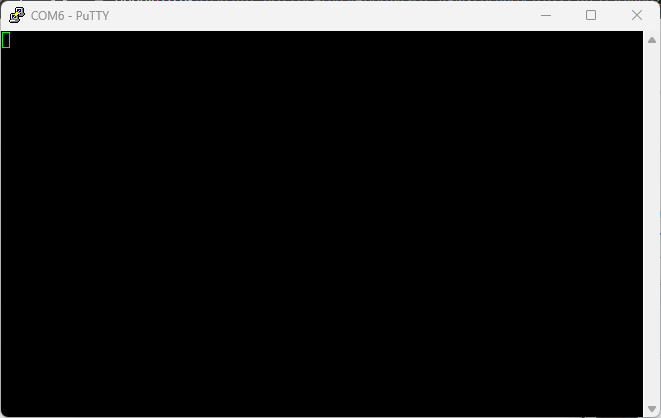

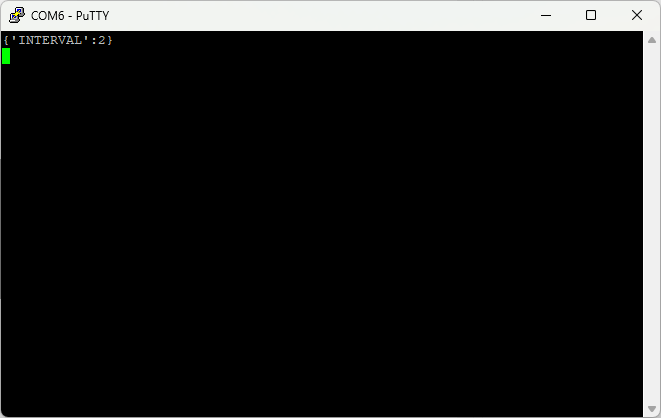

Now press “Open”. You should see a black window appear similar to the following:

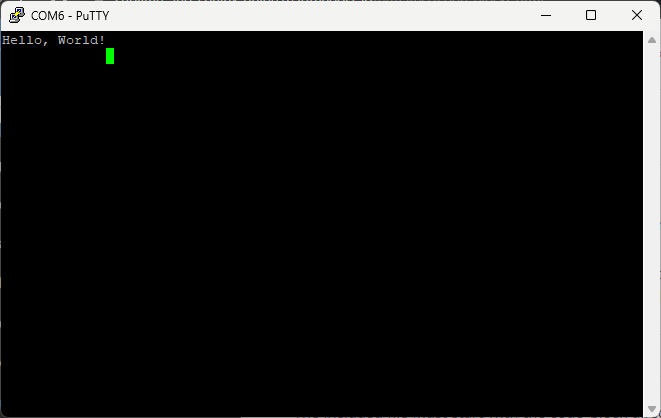

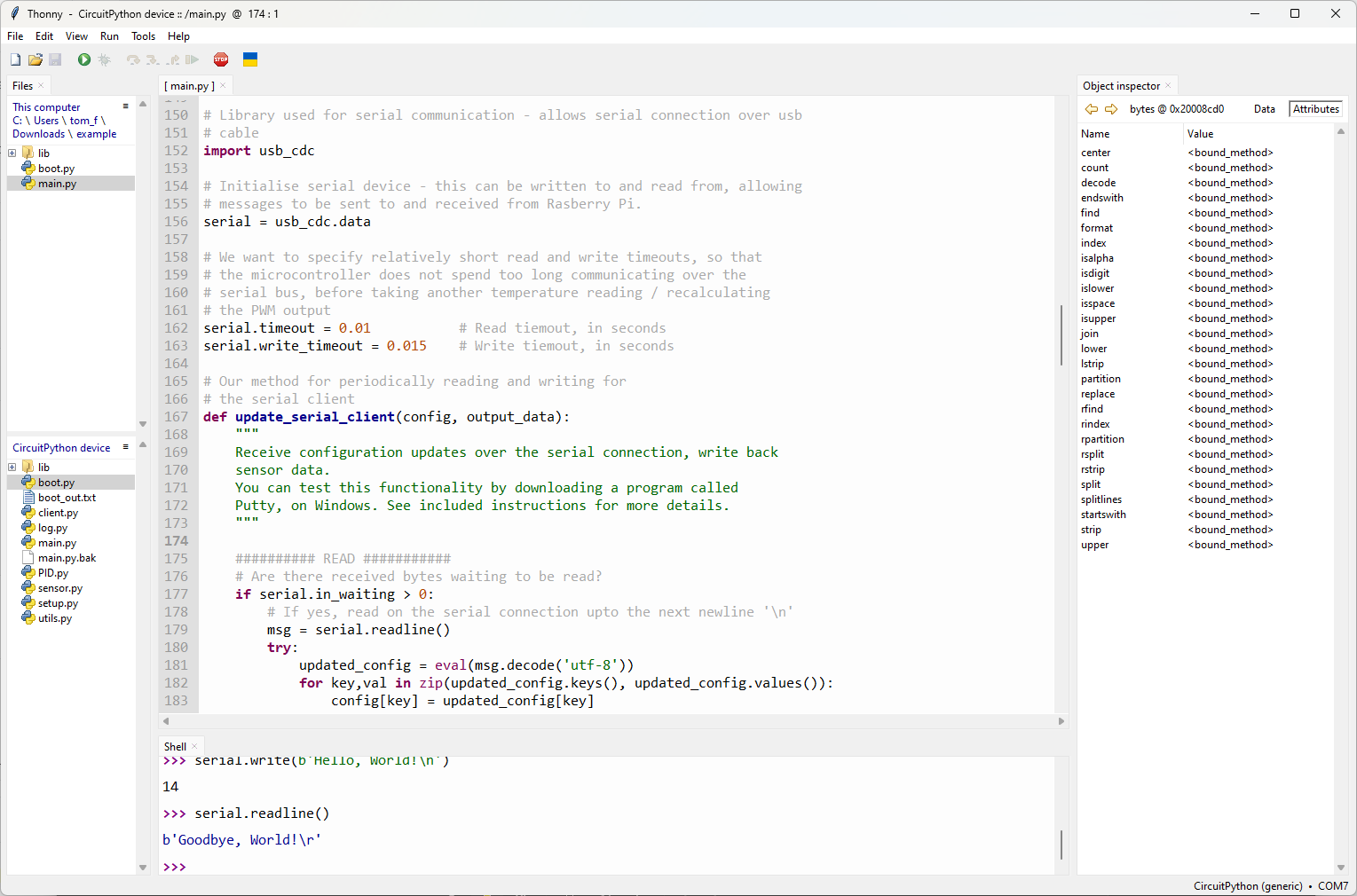

Going back to Thonny, enter the following code in the interpreter shell:

>>> serial.write(b'Hello, World!\n')

Looking in the PuTTY window, you should notice that the following text is now present:

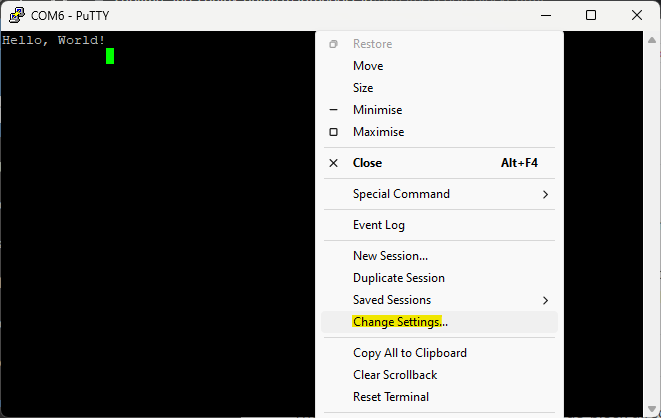

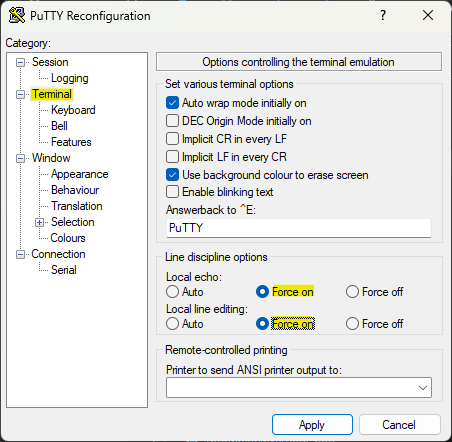

Now, right click the top of the PuTTY window and select “Change Settings”. Select the category “Terminal”, then set the options “Local echo” and “Local line editing” to “Force on”, before clicking “Apply”:

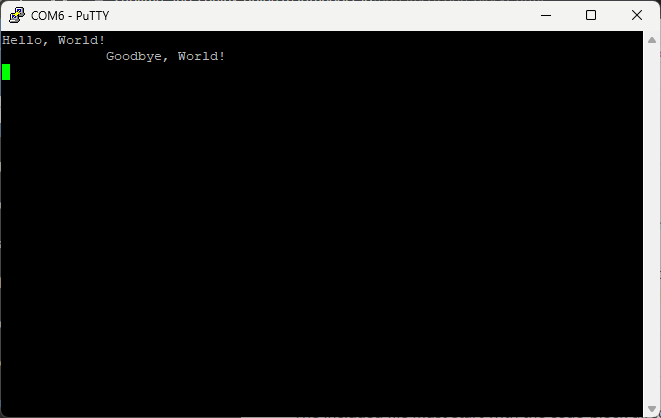

Now, try typing “Goodbye, World!” into the PuTTY window, then press Enter on your keyboard:

Going back to Thonny, now type into the REPL prompt:

>>> serial.readline()

You should see the following message:

Putting it all together¶

By now, you’ve basically seen all of the core library functions used to control the the MCU, when it interacts with the other system components, such as the temperature sensors, H-Bridge and Raspberry Pi.

The remainder of the code, from line 167 onwards, simply utilises these library functions in an organised manner, such that the individual, simple interactions come together to achieve more sophisticated behaviour.

To demonstrate this, try calling the function main.py, in the REPL

prompt:

>>> main()

You should see a stream of messages printing out to the REPL shell, similar to the following:

Can you notice anything about the timestamps - in particular, the time difference between each one?

Try looking at the function definition of main.py, in lines 383-392.

In the function argument, a default argument is specified, consisting

of a python dictionary called config:

383def main(

384 config={

385 'RUN' : False, # Start heating run

386 'MODE' : False, # Switch between heat ramp / temperature hold

387 'LOG' : False, # Start time-stamping

388 'TARGET' : 23, # Target heat rate / hold temperature

389 'KP' : 35.0, # PID proportional gain constant

390 'KD' : 2.0, # PID derivative gain constant

391 'KI' : 3.5, # PID integral gain constant

392 'INTERVAL' : 0.25 # Time interval between readings

393)

Can you see anything interesting about the dictionary element 'INTERVAL'?

Now, going back to the PuTTY window, try typing in the following

{'INTERVAL':2}

and hit Return on your keyboard. What do you notice now about the messages printing to the REPL?

You might want to try entering different commands in the Putty window - however you should take care whenever enabling any options that will result in the TEM heating up:

The config value 'MODE' specifies whether the PID control loop will

attempt to maintain a constant temperature (in degrees Celsius) or a constant

heat rate (in degrees Celsius per minute).

The config value 'TARGET' is used in both cases, to specify either

the set point temperature, or set point heat rate. Therefore, you will see

a big difference in the TEM’s response, depending on the value of 'MODE',

when setting the value of 'TARGET' to say:

{'TARGET':55}

If the value of {'MODE:False'}, the TEM should heat the hot side until

it detects that the attached temperature sensors have reached a temperature

of 55 degrees celsius, at which point it will attempt to maintain that

temperature.

However, if the value of {'MODE':True}, the TEM will attempt to heat

the hot side at a rate of 55 degrees Celsius per minute, which is almost a

degree per second. Not only will this result in dangerous temperatures for

contact with skin in less than a minute, but the microcontroller will

attempt to constantly maintain that heat rate, up to a 100% duty cycle.

For DC power supplies with current supplies greater than 2 Amps, this can lead to thermoelectrc modules heating up to 120-150 degrees Celsius before they self-destruct, due to the internal solder melting.

Therefore, care should be taken when experimenting, and it would be a good idea to not power the TEMs for longer than a couple minutes at most.